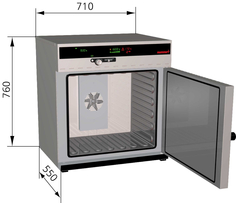

Memmert Universal-Oven UFE Typ 500

Whatever you want to perform: material tests, ageing of computer chips, run complex experiments with highly sensitive loads, drying or tempering electronic components, hardening plastic resin or heating plasticine. Our U universal oven stands for unparalleled precise, even and gentle temperature control.

- Temperature range up to +220 °C (Basic) / +250 ℃ (optionally up to +300 °C)

- 9 model sizes (14l to 749l)

- 3 performance classes Basic/Excellent/Perfect B/E/P

- Natural convection or forced air circulation N/F

State of the art technology

The fittings of this universal oven are practically-oriented, their programme functions are designed for a wide variety of applications, and even when used intensively, our all-rounder made of stainless steel loses nothing in shine or in reliability. From 35 models, expandable with convenient , approved and tested accessories, you will easily find the heating oven ideally suited to your needs. The three controller classes Basic, Excellent and Perfect cover all requirements of thermal safety, precision and quality assurance, building upon each other. |

Memmert Vakuum-Oven Typ VO-500

With short warming up times, high-precision temperature control and turbo-drying, the vacuum oven VO shows off all its strength – at the same time it can handle heat-sensitive or oxygen-sensitive substances and materials such as cosmetics, food, clocks, books or PCBs and other electronic components with unparalleled gentleness when drying. The direct contact between chamber load and the heatable and removable thermal shelves guarantees in all models a quick and even temperature control without loss of heat.

- Temperature range up to +200 ℃

- 3 model sizes (29l, 49l and 1011)

- State-of-the-art control technology based on the P performance class for all models

- Anti-splinter; VDE-tested door construction for all models

Considerabley shorter heating & processing times.

Each of the maximum up to four aluminium thermoshelves that can be inserted as required is equipped with a separate shelf heating and its own sensors. The separate control circuits react precisely to different loads and humidities, and maintain all the levels used equally to the setpoint temperature. Because of the direct contact between heating and chamber load, the heating and operating times are reduced by some 75 per cent compared to a conventional drying oven.

|